Online information session - 3D fashion design training

The fashion and apparel industry is currently experiencing unprecedented growth thanks to digital technology. Mastering 3D tools is becoming…

Investing in finding solutions to the challenges of the circular economy, the Vestechpro team supports its customers in adopting this promising business model that has become a priority for many companies today.

In this context, several strategies are available to clothing stakeholders to best optimize the resources required for clothing manufacture and thus reduce their impact on the environment One strategy is to consider the lifecycle of a product from the development stage, and design a garment whose patterning and cutting will produce minimal fabric scraps.

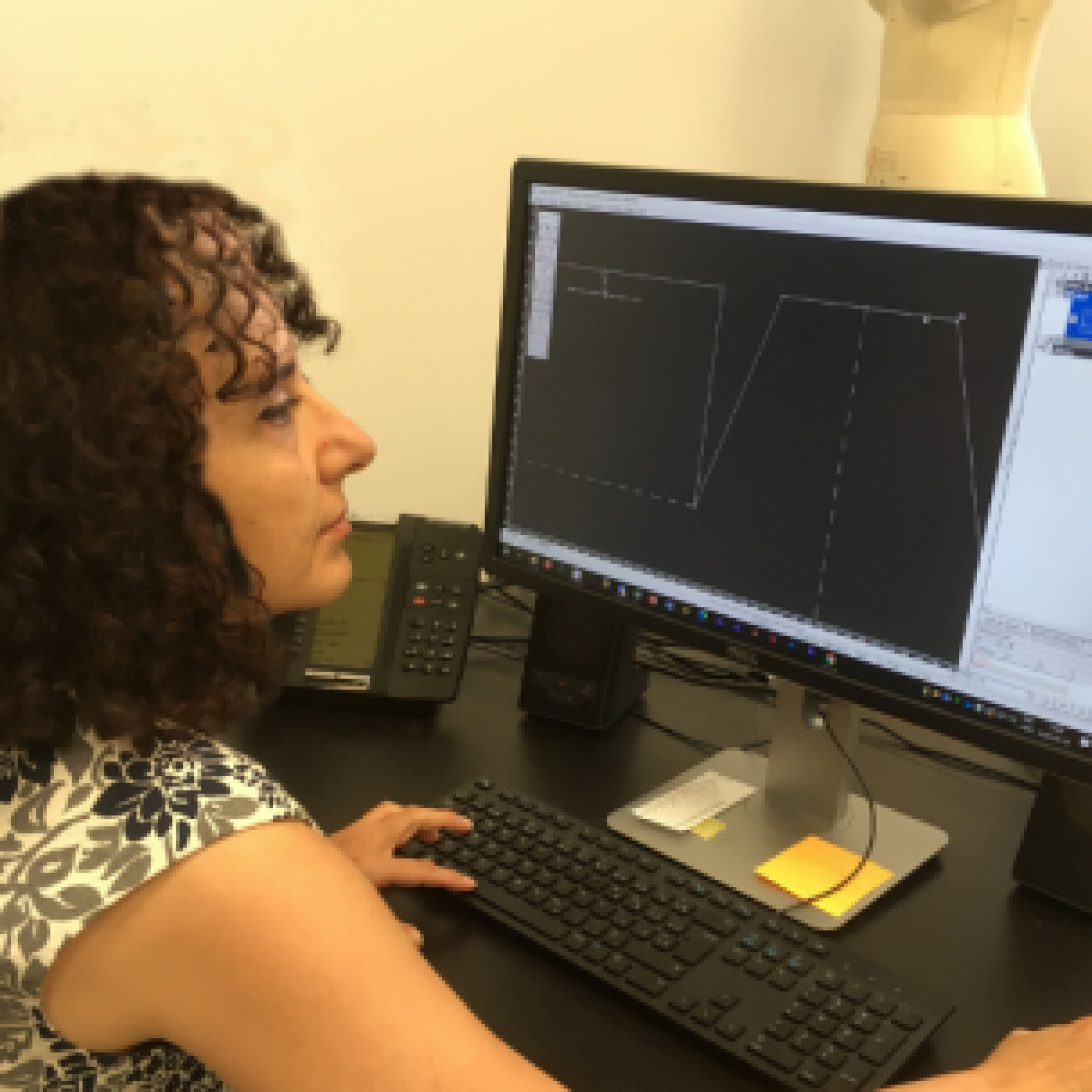

Recently, the mobilization for PPE production has led us to create a zero-waste pattern for medical gowns. We are proud to present to you the approach taken by our Technical Project Manager and Patternmaker, Viktoria, to achieve this.

As she points out, there are three ways to make a zero-waste garment:

Viktoria explains that it is difficult to make a zero-waste pattern for a fitted and elaborate clothing model for industrial production. In fact, each size of each model is developed according to fabric width. The gradation process and sometimes the model design needs to be changed for each size. That’s why the zero-waste pattern is often used a for a loose fit and preferably one- size-fits-all. To make a one-size-fits-all level 2 isolation gown, the zero-waste pattern was essential at the start of the product development process. Our patternmaker has taken care to reduce the number of cuts and seams, as these constitute obstacles to the performance of the garment which is intended to be airtight. In addition, for the assembly of parts, we used the sealed seam technique to make the seams water-repellent and thus guarantee the garment maximum insulating capacity. Finally, our Technical Project Manager was inspired by the kimono to design the gown and reduce the number of scraps. The results were convincing! The new pattern saved 80 cm of fabric per gown, compared to the model cut with the original pattern. Material optimization and reduction of seams reduced the cost of manufacturing the garment and reduced production time: major challenges during the PPE crisis.

Would you like implement this product development approach in your business model?

We can help you develop distinct strategies and advise you according to your projects: contact@vestechpro.com

The fashion and apparel industry is currently experiencing unprecedented growth thanks to digital technology. Mastering 3D tools is becoming…

Do you work for a fashion or apparel company in Quebec? Would you like to identify appropriate strategies, structure and prioritize your circular…

On November 25, 2025, Vestechpro took part in the Circular Economy Meeting – Textile Sector organized by Granby Industriel at the Granby Industrial…

This fall, Vestechpro opened the doors of its Shared Lab and facilities, giving several students from Cégep Marie-Victorin the opportunity to immerse…